Introduction

In the fast changing world of technological developments, two major players have developed in the race for industrial innovation: IOT(Internet of Things) or Cobots (Collaborative Robots ). Both technologies offer to transform industry, simplify procedures, and increase productivity.

In this blog post, we will look at the unique features, uses, and advantages and disadvantages of IoT and Cobots to see which has the advantage in shaping the future.

1. Awareness of the IoT

The Internet of Things (IoT) is a large network of interconnected devices, sensors, and systems that seamlessly communicate and share data via the internet.

IoT’s major goal is to build a smart and efficient environment in which devices can gather, analyze, and act on data in real time.

This connectivity enables increased automation, improved decision-making, and higher productivity in a variety of areas.

2. Applications of IoT

Healthcare:

- Monitoring Patient Vitals: IoT devices provide real-time monitoring of patient health indicators.

- Data Transmission: Sending health information to medical professionals for remote monitoring and analysis.

- Emergency reply: Automating emergency reactions based on collected information.

Agriculture:

- Soil Conditions: IoT sensors analyze soil conditions for targeted farming.

- Weather Patterns: Weather conditions are monitored in order to maximize crop cultivation methods.

- Crop Health: Using IoT to track and evaluate crop health so that farmers may make informed decisions.

Manufacturing:

- Process Optimization: Implementing IoT in manufacturing allows for real-time monitoring and optimization of processes.

- Predictive maintenance: Is the use of IoT sensors to predict equipment breakdowns and plan maintenance at the right time.

- Supply Chain Visibility: Improving supply chain visibility with IoT-enabled surveillance and tracking.

Logistics:

- Fleet management: It involves real-time tracking and management of vehicles and shipments through IoT technology.

- Inventory Monitoring: Implementing IoT to monitor levels of stock and improve logistics operations.

- Route optimization: It involves utilizing IoT data to optimize delivery routes for efficiency.

Smart cities:

- Energy Management: Using IoT to efficiently monitor and manage energy consumption.

- Waste reduction: It involves optimizing collection routes using efficient waste management systems.

- Traffic optimization: It involves real-time monitoring and optimization using IoT data.

3. Understanding cobots

Collaborative Robots, or Cobots, were developed for working together people in an office environment that is shared.

Cobots, unlike standard industrial robots, have superior sensors and security features which enable them to work among humans without harming them.

This collaborative character creates new opportunities for automation in industries where human-robot collaboration is important.

4. Applications of Cobots

Manufacturing:

- Repetitive Task Assistance: Cobots are used to assist with tasks that are repeated, increasing production efficiency.

- Better Quality: Their use helps to improve product quality by guaranteeing accuracy and stability.

Healthcare:

- Medication Delivery: Cobots can be used to distribute drugs to patients in an effective and precise manner.

- Patient Assistance: Assisting medical professionals with patient treatment and support.

Logistics

- Warehouse Streamlining: Cobots help simplify the management of warehouses, improving productivity.

- Inventory management: involves automating operations such as supply counting.

- Order Fulfillment: Working in order fulfillment processes to meet client needs on time.

Construction:

- Bricklaying Assistance: Cobots help in construction jobs like bricklaying by improving precision and speed.

- Welding Support: Assisting with welding procedures to improve efficiency and provide high-quality welds.

Service Industry:

Customer Assistance: Cobots are used for tasks related to customer service such as help and information.

Task automation is the process of automating normal jobs in the service sector in order to improve efficiency in operations.

5. What are the differences between IoT and Cobots

1. Flexibility and adaptability of Iot and Cobots:

- IoT is strong in flexibility and adjustment, fitting smoothly into a wide range of data transfers and communication platforms.

- Cobots, while designed for partnership, may be less adaptive in some situations.

2. Automation Capabilities of Iot and Cobots:

- Both IoT and Cobots are related with automation, although in different ways. The Internet of Things automates gathering information, processing, and decision-making processes.

- Cobots automate physical duties in partnership with human workers. The decision is based on the industry’s automation requirements, with some applications benefiting from a mix of both technologies.

3. Human Interactions of Iot and Cobots:

- Cobots offer a unique the advantage in terms of human interaction.

- Their design focuses safety, with built-in sensors that identify and react to human activity.

- While strong, the Internet of Things communicates with systems and objects instead of with humans.

4. Price and deployment of Iot and Cobots:

- modifying current equipment with sensors and connection features might make IoT implementation cheaper.

- Cobots might require an initial investment of more money because to particular hardware and safety requirements. Saving money is determined by industry specific requirements.

5. Data Security and Privacy:

- Because of its large network, IoT offers data security problems that necessitate strong cybersecurity solutions.

- Cobots, because they are more restricted, may be less at risk of hacking of data, but the data they gain must still be managed with care.

6. Scalability of Iot and Cobots:

- IoT solutions are highly scalable, allowing for easy integration of new devices.

- Cobots are scalable, but as the number of robots in a shared workspace grows, careful planning becomes increasingly necessary.

7. Skill requirements for Iot and Cobots:

- Experience in data analytics, networking, and software development is required when implementing IoT systems.

- Cobots have been designed to be simple to use, requiring little programming or technical knowledge to use.

8. Downtime & Maintenance:

- IoT systems may go down because of connectivity challenges, software errors, or hardware failures.

- Cobots are built for confidence, with built-in monitoring and maintenance planning capabilities.

9. Industry Specific Considerations:

- Different industries have different demands, and the choice is based on individual use cases.

- Cobots develop at certain physical activities, whereas IoT improves decision-making based on data and connectivity.

10. Return of Investment (ROI):

- To calculate the ROI for both technologies, consider elements such as increased efficiency, cost savings, improved quality, reduced downtime, and the impact on the environment.

- The time frame for experiencing these benefits could differ.

Conclusion

The choice between IoT and Cobots is not about which is better but about knowing their respective capabilities and applications.

Industries gain from an intelligent combination, using both technologies to create an effective and prepared for the future solution.

As industries develop, the integration of IoT and Cobots will play an important role in creating smart, efficient, and collaborative workplaces.

The key is strategic planning, taking into account each industry’s particular demands, and recognizing the revolutionary potential that will result from the combination of these revolutionary technologies.

Related posts

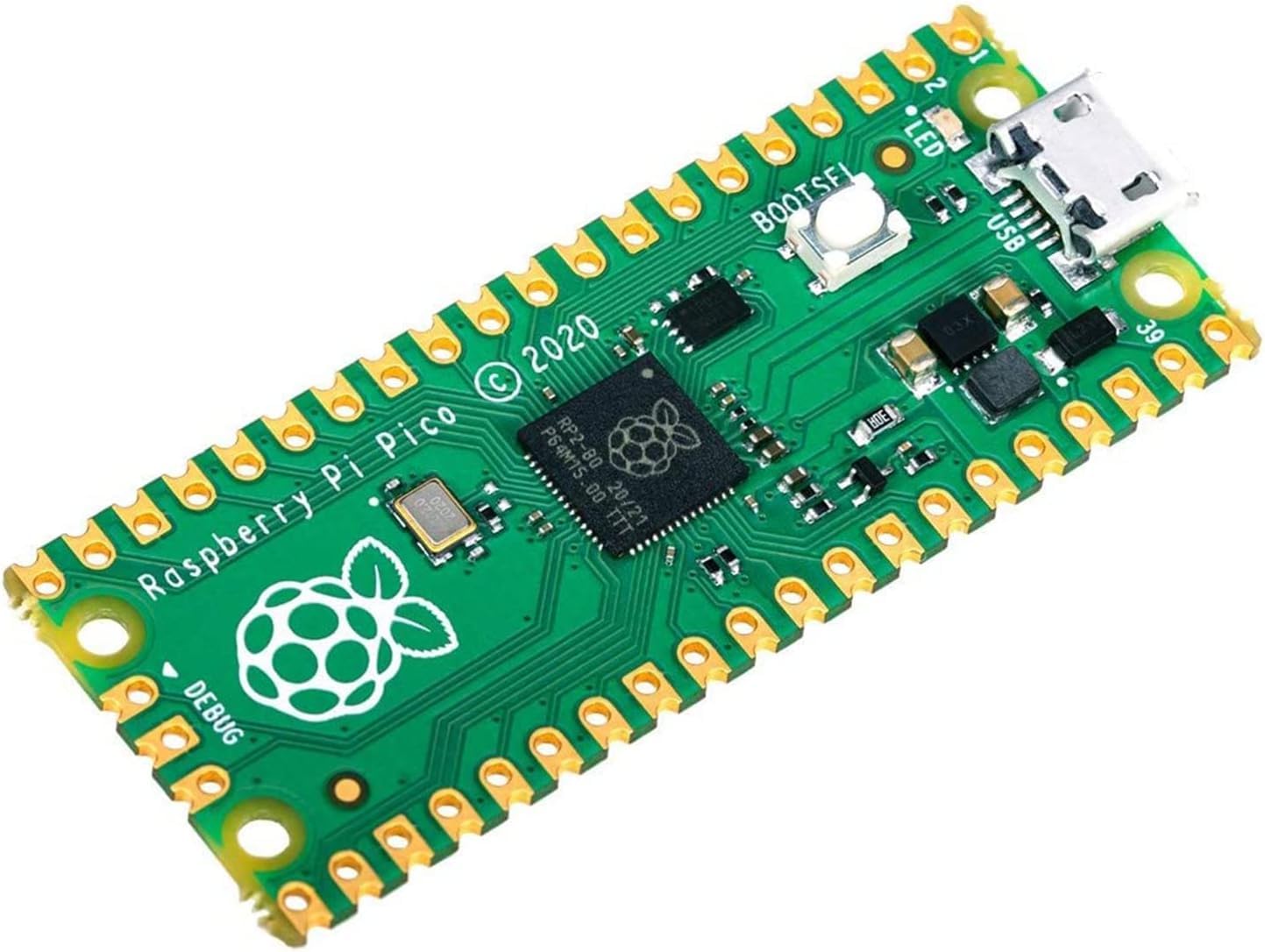

1. Is ESP32 more powerful than Raspberry Pi Pico?

2. Is ESP8266 better than ESP32?

3. Advantages And Disadvantages Of ESP8266 Wi-Fi Module

4. Home Automation using Arduino and hc-05 Bluetooth module

5. What Microcontroller Used MicroPython?

6. ESP32 with Micropython to control electrical devices using a relay

7. How AI and IoT Impact Daily Life

9. What is the difference between robots and cobots?

10. What is an ( AGVs) automated guided vehicle?

11. Advantages and disadvantages of humanoid robots

12. Why are robots better at doing repetitive tasks than humans?

13. Where are articulated robots used the most?

1 thought on “Which Is Better IOT or Cobots”