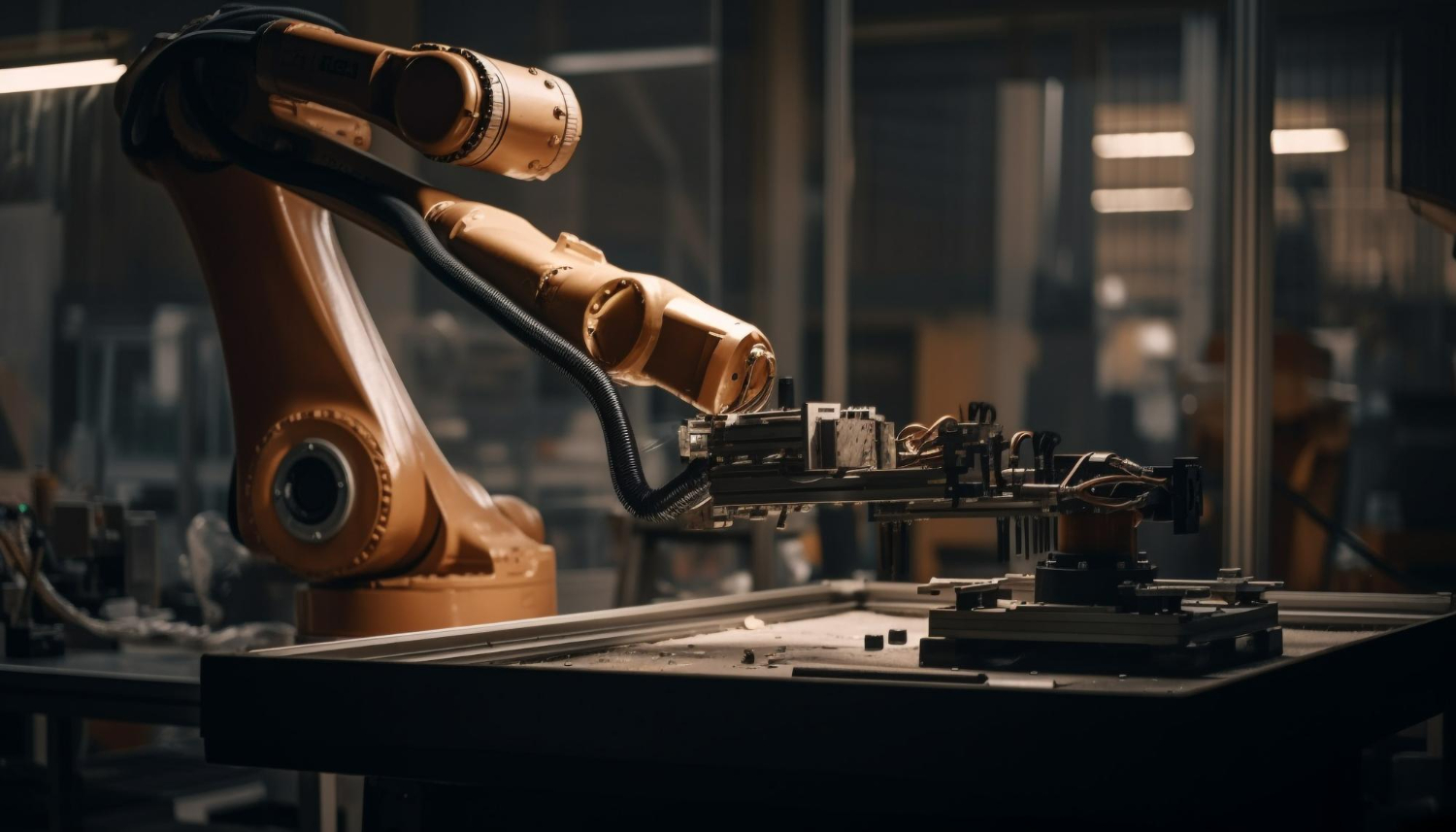

Introduction: Cartesian Robots

In the field of industrial automation, Cartesian robots have grown up as useful tools, providing accurate and effective solutions for a wide range of applications.

These robots, also known as gantry or rectilinear robots, move across three linear axes, making them extremely adaptable and flexible to a variety of manufacturing settings.

In this blog post, we will look at the benefits of Cartesian robots and why they are used in modern automation operations.

Advantages of Cartesian Robots

1. precision and accuracy of Cartesian robots :

- These robots excellent at both accuracy and precision, making them highly advantageous.

- With exact control over each axis of movement, these robots can carry out jobs with little tolerance for mistake, providing high standards in production operations.

- These robots specialize in providing exact outcomes, whether assembling small electronic components or performing advanced machining tasks, which improves product quality and reliability.

2. Flexibility and Customization of Cartesian robots :

- These robots offer outstanding versatility and customization choices, making them excellent for different manufacturing applications.

- These robots, compared to other types of robots, are easily customizable to meet individual application requirements.

- Whether it requires modifying the reach, cargo capacity, or workspace size, these robots may be adjusted to fit various production demands.

- With this flexibility, manufacturers may configure their automation systems for maximum effectiveness and productivity.

3. Scalability and adaptability of Cartesian robots :

- Another advantage of these robots is their scalability and adaptability, which allow for simple integration into present facilities and future growth.

- These robots may be quickly scaled up or down to meet changing production levels without requiring extensive reconfiguration or investment in whole new systems.

- Furthermore, their flexible design enables for the installation of new axis or end-effectors to meet developing industrial needs.

- As a result, businesses may respond immediately to market demands while maintaining a competitive advantage in the sector.

4. Ease of programming and operation of Cartesian robots :

- These robots are well-known for the simplicity of programming and operation, thanks to simple software interfaces and common programming languages.

- Operators can quickly build and alter robot paths using user-friendly programming environments such as graphical interfaces or offline simulation tools, even if they lack considerable robotics programming training or experience.

- Furthermore, the simple mechanical structure of these robots makes troubleshooting and maintenance easier, minimizing downtime and improving overall system reliability.

5. Cost-effectiveness of Cartesian robots :

- These robots, as opposed to other types of robots, are frequently a low-cost solution for a wide range of automation applications.

- Their simpler mechanical design and common parts result in a smaller initial investment and lower long-term maintenance spending for the robot.

- In addition, of these robots’ flexibility and recycling help to save long-term costs by eliminating the requirement for specialist equipment or costly redesigning during manufacturing modifications.

- As a result, companies might see a faster return on investment and increase their bottom line.

6. High Payload Capacity of Cartesian robots :

- These robots can handle heavy weights with ease because to their solid build and strong structure.

- Because of their great payload capacity, they are ideal for applications requiring the lifting and handling of heavy or bulky objects, such as material handling in warehouses or automobile assembly lines.

- These robots improve industrial speed and productivity by efficiently managing high payloads.

7. Flexibility in end-effector integration of Cartesian robots:

- These robots are flexible in that they can integrate a variety of end-effectors or tooling systems to complete specific jobs.

- Whether it’s grabbing, welding, painting, or distributing, these robots can support a variety of end-of-arm tools alternatives to meet various application needs.

- This adaptability allows manufacturers to simplify production processes and respond to new product designs or manufacturing techniques without requiring considerable reconfiguration.

8. Consistent performance of Cartesian robots:

- These robots operate regularly throughout long times of operation thanks to its powerful frame and advanced control mechanisms.

- compared to human workers, whose productivity may vary due to tiredness or skill level variations, robots work at a continuous pace and follow to specified tasks, assuring constant standards and productivity.

- This dependability is especially useful in businesses where consistency and regularity are essential, such as electronics production or packaging for medicines.

9. Improved workplace safety of Cartesian robots:

- These robots help to improve workplace security by automating repetitive or dangerous operations, reducing the chance of accidents and injuries caused by human error.

- These robots may operate in situations with extreme temperatures, poisonous chemicals, or limited areas where human presence could constitute a safety risk.

- These robots can also be supplied with enhanced safety features like as damage warning sensors and emergency stop systems, which reduces the possibility of accidents at work.

10. Integration of Industry 4.0 technologies in Cartesian robots:

- Cartesian robots perform an important role in the execution of Industry 4.0 efforts by acting as fundamental parts of smart manufacturing systems.

- These robots can monitor and optimize manufacturing processes in real time thanks to their connectivity with sensors, actuators, and data analytics systems.

- Companies may improve efficiency, minimize downtime, and maximize resource usage by accepting data-driven insights, resulting in constant improvement and innovation in their operations.

11. Adaptability to challenging environments of Cartesian robots:

- These robots are well-suited for use in demanding areas such as clean rooms, hazardous industrial settings where strict environmental standards must be followed.

- These robots, which have sealed housings and specific finishes, are able to endure dust, moisture, and acidic substances without sacrificing performance or dependability.

- Cartesian robots’ adaptability makes them essential for applications in industries such as semiconductor production, medicines, and food processing.

12. Improved time-to-market of Cartesian robots:

- Cartesian robots help to reduce lead times and accelerate manufacturing cycles, resulting in a shorter time to market for creative ideas items.

- These robots, with their speed, precision, and automation capabilities, help manufacturers simplify their prototype, testing, and manufacturing processes, allowing items to reach customers faster.

- This adaptability is critical in highly competitive businesses that require quick invention and reaction to market demands.

Conclusion: Cartesian Robots

Finally, Cartesian robots have many benefits, making them essential components in modern automation.

These robots allow manufacturers to increase efficiency, quality, and workplace safety. They combine precision and flexibility with scalability and cost-effectiveness.

Furthermore, they have a large carrying capacity and adaptability in end-effector integration. They provide dependable operation and enhanced worker safety.

In addition, they work perfectly with Industry 4.0 technologies. They are adaptable to tough situations. In addition, they improve speed to market skills.

Cartesian robots are likely to maintain their leadership in automation. with their adoption driving efficiency, innovation, and productivity across a wide range of industries.

Related posts

1. Which Is Better IOT or Cobots

3. What is the difference between robots and cobots?

4. What is an ( AGVs) automated guided vehicle?

5. Advantages and disadvantages of humanoid robots

6. Why are robots better at doing repetitive tasks than humans?

7. Where are articulated robots used the most?

1 thought on “Cartesian Robots: Advantages in Modern Automation”